Remaining 5 press working operations.

Notching operation in sheet metal.

It is an operation by which multiples holes of smaller size are made in sheet metal called.

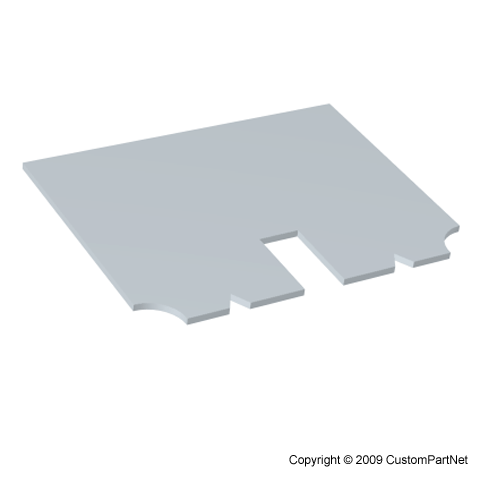

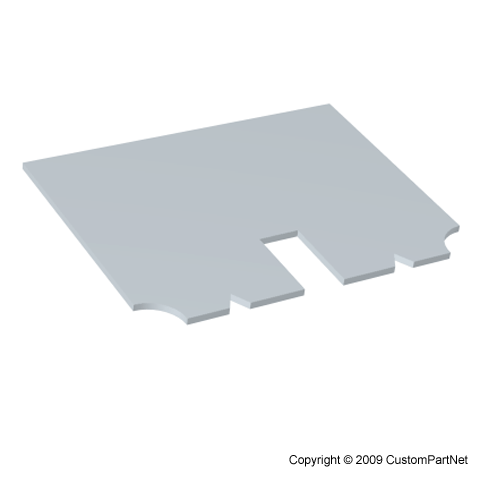

Notching is a shearing process during which a metal scrap piece is removed from the outside edge of a metal workpiece.

V notching operation for sheet metal bending.

Removing and trimming and creating notches at the edge.

Sheet metal trimming operation duration.

Notching is the process where shapes are cut from the edges of the sheet metal.

Notching is often performed as a progressive process each operation removing another piece to make the correct contour.

Notching is a type of sheetmetal cutting operation to remove material from the work piece.

Take all measurements from the datum edge and the squared vertical line as these are now accurate.

Notching is a metal cutting process used on sheetmetal or thin barstock sometimes on angle sections or tube.

Draw in all vertical and horizontal lines to develop the required pattern.

A shearing or punching process is used in a press so as to cut vertically down and perpendicular to the surface working from the edge of a work piece.

The objective of notching is to create a sheet metal part with a desired profile.

Notching is a metal cutting process used on sheet metal or thin bar stock sometimes on angle sections or tube.

Sheet metal forming operations.

Notching is a sheet metal cutting process that involves the removal of material from a work piece starting at the edge and cutting inward.

Trimming in sheet metal trimming involves the removal of excess material from the perimeter of the workpiece.

It is an operation by which metal pieces are cut from the edge of a sheet or blank is called a.

The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing in this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles.

Forming operations cause stress below the sheet metal s ultimate strength resulting in distortion.

Vishal sonawane 4 849 views.

Mainly sheet metal process can be divided into three types.

Square up the bottom left hand side of the sheet using a large metal square and scribe a line 5mm from the left edge using the bottom of the sheet as a datum edge.

Unique idea from broken lifting jack.